Description

BD-V7EX series Multi Injection System

Model: BD-V7EX

PHOTOS

FEATURES

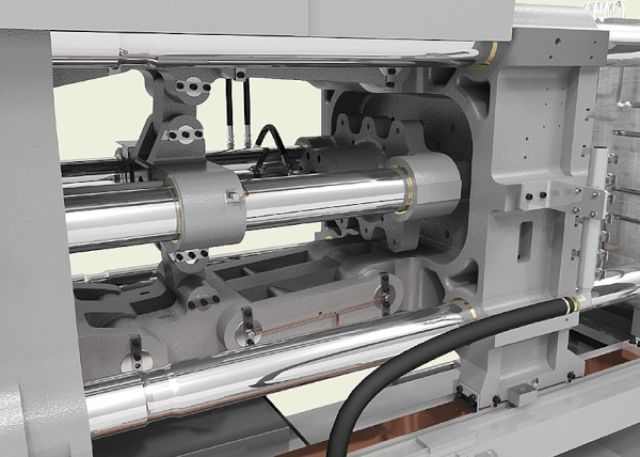

■THRV System

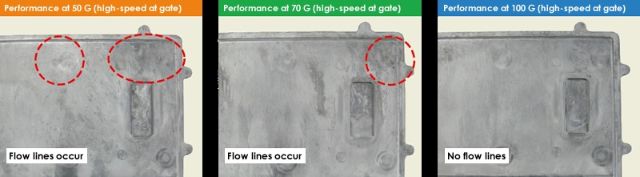

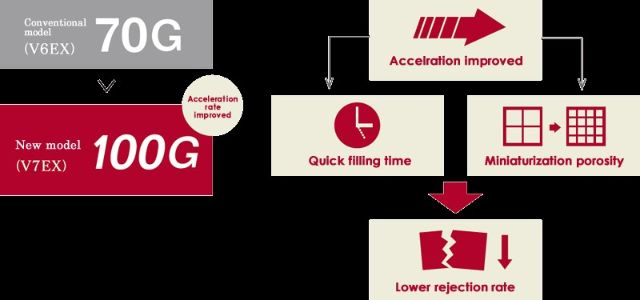

| With original THRV System* developed by TOYO, higher acceleration, the most important casting capability, can be provided with standard machines. |

|

| Product outline comparison

Reduced filling time shorter can complete injection before the surface solidifies.

|

| ※THRV System:TOYO High Response Valve System (Patent pending) |

■New control System700EX

| System700EX was developed with four overall requirements: Visibility,Functionality,Maintainability,and Usability, to improve the functionality based on feedback from users. |

|

|

|

| Visibility | Functionality |

| ‧Visualized machine

‧Sophisticated design |

‧Higher injection graph performance

‧Alarm display ‧Improved start up function ‧Supports automatic molten metal discharge |

| Maintainablility | Usability |

| ‧Alarm detail display

‧Injection circuit display |

‧Cumulative monitoring data display function

‧Backup data can be stored by users ‧Graph data can be saved in CSV format ‧Increase the number of data sets in history&saving in CSV format |

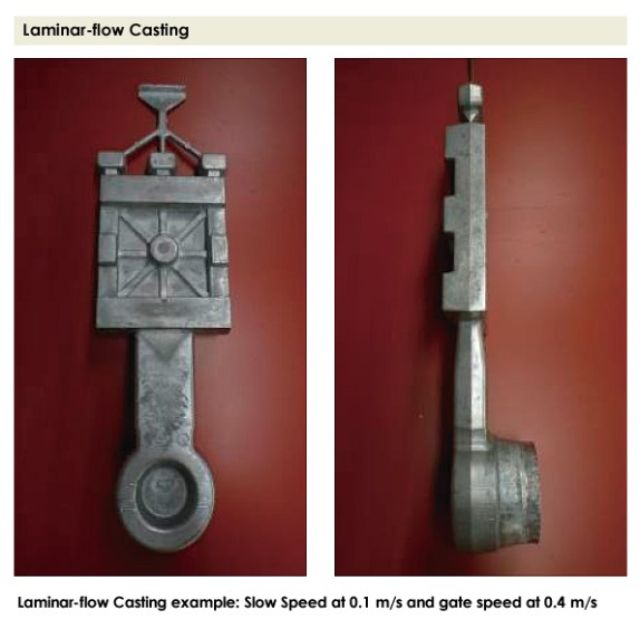

■Injection control

TOYO’s Injection system.

Meter-IN/OUT control can be selected.

| Meter-in control | Meter-out control(optional) |

| Features | Features |

| ‧Velocity stability in the Super Slow Speed range

‧Shorter pressure increase time ‧Controls pressure increase start |

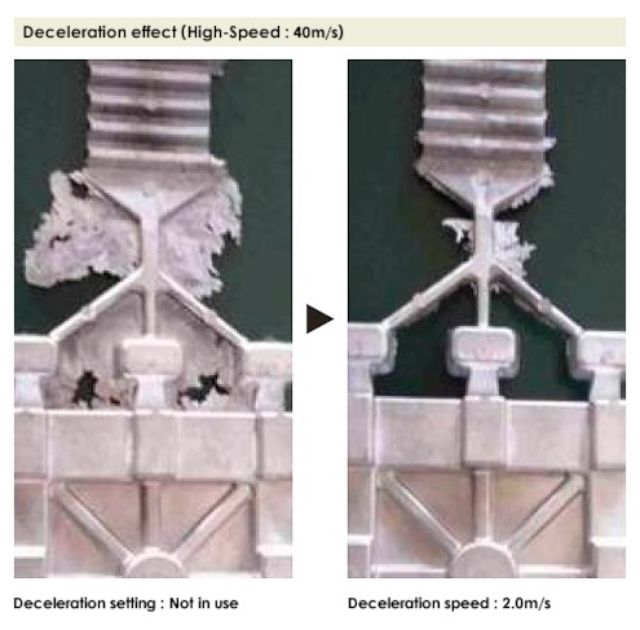

‧Performs High-Speed acceleration adjustment

‧can be setted multiple speeds at high speed range ‧Decreases the injection surge pressure using the High-Speed deceleration function |

| Effect | Effect |

| ‧Supports pressure resistant products and laminar-flow die casting

‧Suitable for Pore Free Casting ‧Natural flow(Casting with natural flow) |

‧Effective to decrease burrs and protect molds

‧Suitable for thin product casting ‧High-Speed forced control |

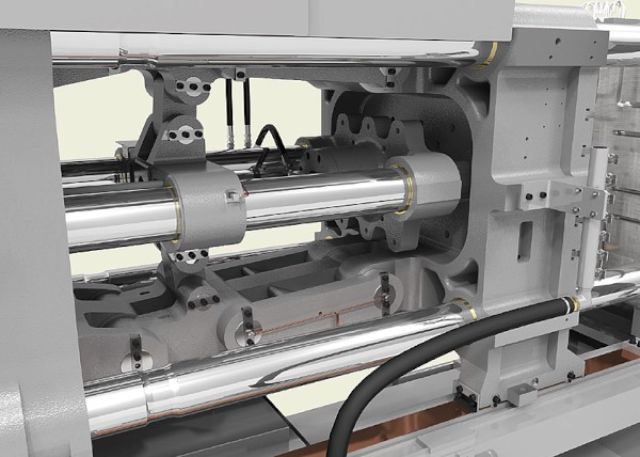

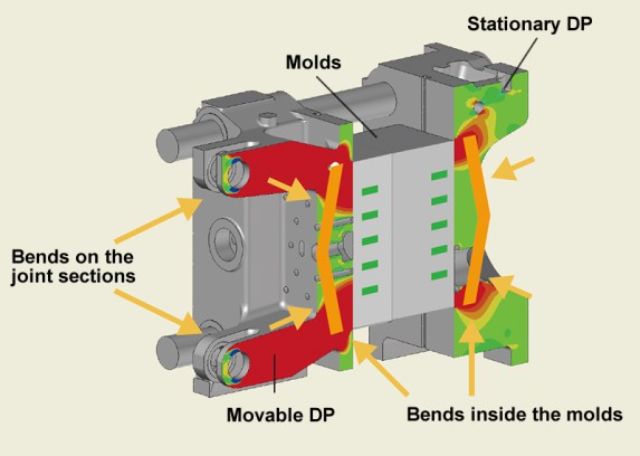

■Mold clamping center press mechanism

| Supports molds with specifications that are one rank higher High-precision, High-rigidity mold clamping mechanism |

|

| ‧The guide bar mechanism provides higher precision and mold clamping rigidity.

‧The center press mechanism minimizes bending of the mold mounting areas. ‧By lowering the injection position, so it supports dies with specifications that are one rank higher. |

|

| Optimized stationary and movable DP shapes

Decreased bending |

|

| ‧The optimally designed die plate minimizes bends through CAE analysis.

‧The optimal casting is achieved by applying even clamping force to the mold parting lines. ‧Minimizing bending and then decreases burrs. |

|

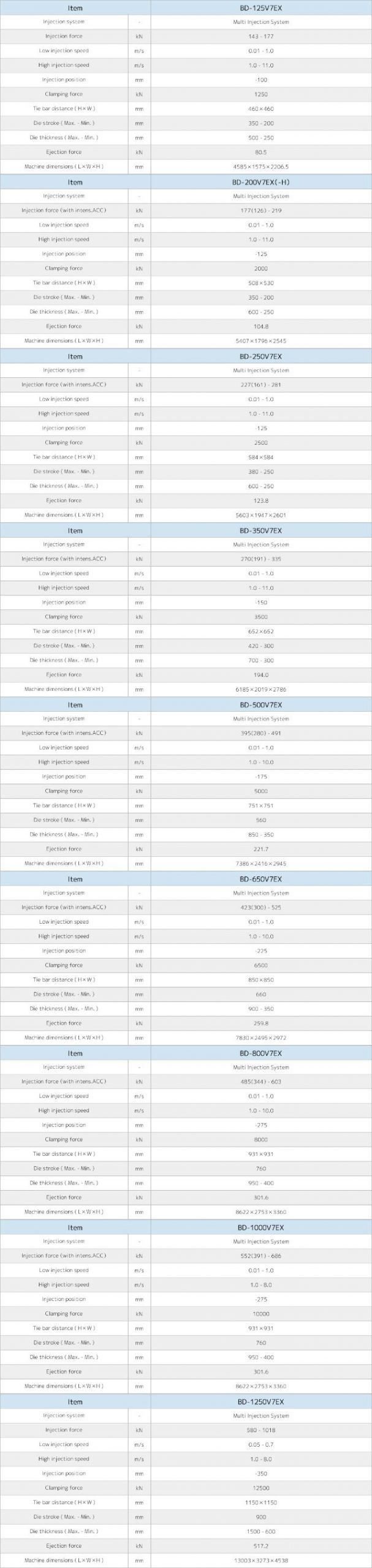

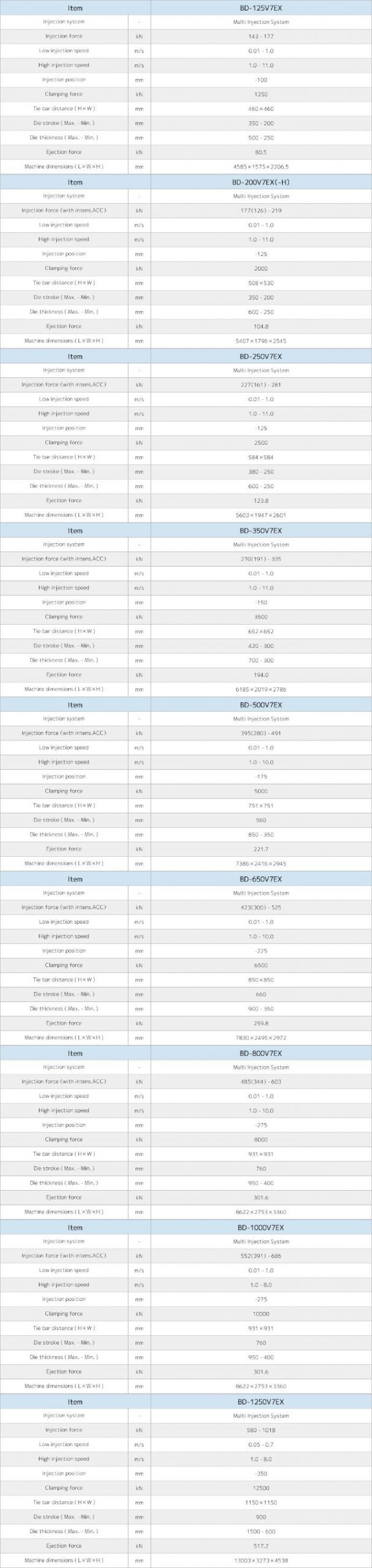

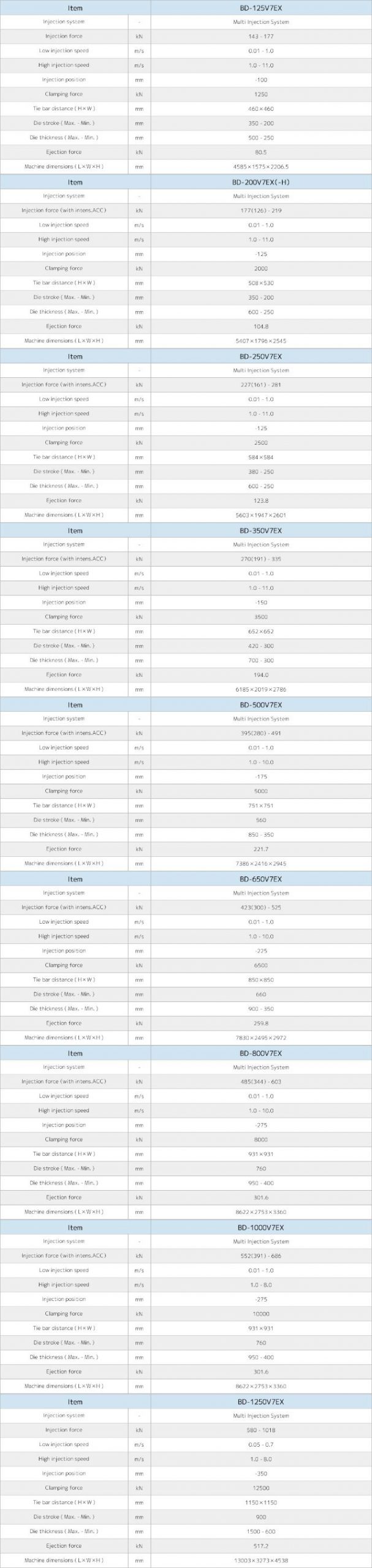

SPECIFICATIONS